How Quantitative Optical Gas Imaging (QOGI) enables continuous measurement of low-rate methane leaks in LPM using dual-band OGI technology

Methane leak detection has become a central pillar of emissions management as regulators, investors, and sustainability leaders intensify their focus on near-term climate impact and operational accountability. While large methane releases draw immediate attention, the majority of emissions across industrial facilities often originate from small, low-rate leaks that persist continuously and remain undetected by conventional monitoring approaches.

These emissions rarely trigger alarms, seldom appear in incident reports, and are frequently underrepresented in emissions inventories. Over time, however, they accumulate into a significant environmental, financial, and reputational risk, particularly when organizations are unable to demonstrate accurate and continuous monitoring.

This article examines why small methane leaks represent one of the most overlooked challenges in methane leak detection, how traditional approaches fail to capture them, and how Quantitative Optical Gas Imaging (QOGI), enables continuous, actionable quantification in liters per minute, LPM.

Why Small Methane Leaks Are the Biggest Blind Spot in Emissions Monitoring

Small methane leaks typically occur at flow rates that fall below the detection thresholds of many traditional monitoring systems. Unlike major leaks that create safety events or visible operational disruptions, low-rate emissions often blend into background conditions and continue unnoticed for extended periods.

Individually, these leaks may appear negligible. Collectively, they can account for a substantial portion of total facility emissions. Because they persist between inspections, they often escape detection during periodic surveys, creating a gap between reported emissions performance and actual environmental impact.

The ESG and Regulatory Risk of Undetected Low-Rate Emissions

Environmental, Social, and Governance reporting increasingly emphasizes transparency, consistency, and data-driven validation. Methane emissions are no longer assessed solely through estimates or periodic inspection records. Stakeholders expect demonstrable evidence that emissions are actively monitored, quantified, and reduced over time.

Undetected low-rate methane emissions introduce multiple risks. Emissions inventories may understate true releases, compliance assessments may lack defensibility, and sustainability claims may be challenged during audits or regulatory reviews. In this context, continuous and quantified methane data is becoming essential to credible ESG performance.

Why Conventional Methane Leak Detection Misses Small Leaks

Most conventional methane leak detection approaches are designed to identify discrete events rather than continuous behavior. They rely on inspections performed at fixed intervals, often under constrained environmental and operational conditions.

This snapshot-based methodology creates structural limitations. Low-rate leaks may fluctuate below detection thresholds, disperse quickly, or occur outside inspection windows. Even when detected, these leaks are rarely quantified in a way that reflects their cumulative impact over time.

As a result, conventional methane leak detection can confirm the presence of leaks without providing the insight needed to understand their true contribution to total emissions.

Why Periodic LDAR Surveys Miss Continuous Leaks

Leak Detection and Repair programs remain a foundational element of methane management strategies. However, their periodic nature introduces inherent constraints.

LDAR surveys are conducted at discrete moments and provide only a partial view of emissions behavior. Low-rate leaks that persist between inspections can remain active for long

periods without intervention. In many cases, detection is decoupled from meaningful quantification, limiting the ability to prioritize repairs or validate mitigation outcomes.

Periodic detection alone is therefore insufficient to capture the full scope of methane emissions across complex industrial environments.

From Visualization to Quantification: What QOGI Really Means

Optical Gas Imaging transformed methane leak detection by making invisible gas plumes visible. Traditional OGI systems, however, primarily indicate whether gas is present. While this capability is valuable for locating leaks, it does not provide the information required to assess their impact.

Quantitative Optical Gas Imaging extends OGI by estimating emission rates rather than simply visualizing gas. QOGI translates optical data into measurable flow rates, enabling operators to understand how much methane is being released and at what rate. This shift from visualization to quantification is critical for emissions management, prioritization, and reporting.

Measuring Methane Leaks in LPM: Why This Metric Matters

Liters per minute is a practical and meaningful metric for methane emissions. Unlike concentration-based indicators, LPM represents the actual volume of gas released over time.

Measuring leaks in LPM allows operators to compare emissions across assets, prioritize corrective actions based on impact, and aggregate emissions data for reporting and analysis. It also supports validation of mitigation efforts by enabling before-and-after comparisons that reflect real operational outcomes rather than qualitative observations.

How Dual-Band OGI Enables Accurate Quantification of Small Leaks

Quantifying low-rate methane leaks requires stable measurements in dynamic industrial environments. Dual-band Optical Gas Imaging improves measurement reliability by capturing complementary spectral information, allowing methane signatures to be distinguished more effectively from background effects such as thermal variation or reflected radiation.

This approach enhances sensitivity to small emissions and supports consistent quantification under changing conditions. When combined with continuous monitoring, dual-band QOGI transforms small, persistent leaks into measurable data streams that can be tracked and addressed over time.

Solutions such as the MetCam platform from CI Sensing implement dual-band QOGI in fixed monitoring configurations, enabling continuous quantification of low-rate methane emissions under real operational conditions.

In the video below, a real-world example of how continuous optical gas imaging can uncover a small, persistent methane leak that would likely remain undetected through conventional inspection approaches:

Real-World Validation Through Continuous Monitoring Deployments

Field deployments demonstrate the practical value of continuous methane quantification across a range of industrial environments.

1. In pressure reduction and metering stations, fixed optical gas imaging systems have been used to detect and log low-rate methane emissions over extended periods, generate automated alerts, and produce emissions summaries that support both safety oversight and regulatory readiness.

Optical Gas Imaging (MetCam®) at Eshel HaNassi PRMS Station

2. In geothermal power plants, continuous optical gas imaging has provided persistent coverage of high-risk components, enabling early identification of leaks, improved maintenance planning, and enhanced situational awareness.

CI Sensing’s MetCam unit in Ormat Neal Hot Springs geothermal power plant, Oregon

3. Unmanned compressor stations benefit from continuous monitoring by reducing reliance on manual inspections, validating alarms remotely, and improving both safety and emissions control in hard-to-access locations.

MetCam at a compressor site in the Cooper Basin.

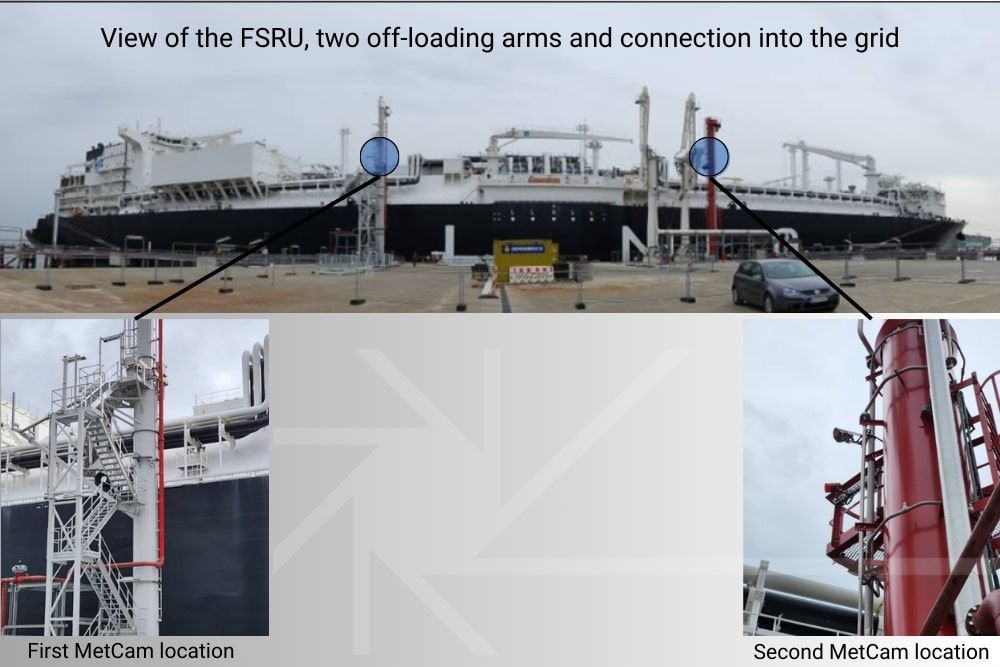

4. LNG import terminals represent another critical application. These facilities involve extensive transfer infrastructure, multiple potential leak points, and strict regulatory oversight.

Applying stationary OGI to monitor hazardous methane leaks at FSRU off-loading arms

Continuous optical gas imaging enables persistent monitoring across hazardous zones, early detection of low-rate methane leaks, and quantifiable emissions data that supports both operational safety and compliance requirements.

In such environments, the ability to quantify emissions continuously is particularly important due to the scale, complexity, and visibility of LNG operations.

Together, these deployments illustrate how continuous quantification bridges the gap between detection and actionable emissions management.

Practical Implications for ESG Reporting and Operations

When methane emissions are continuously quantified, organizations gain a clearer understanding of their true emissions profile. Chronic emitters can be identified, mitigation efforts can be validated, and emissions data can be integrated into operational and sustainability workflows.

For ESG teams, quantified continuous data strengthens disclosures and supports credible reporting. For operations teams, it provides a data-driven basis for prioritizing maintenance, allocating resources, and reducing long-term risk.

Closing the Small-Leak Gap

Small methane leaks are not a minor concern. They represent a persistent and often underestimated source of emissions that can undermine both environmental performance and stakeholder trust. By moving beyond periodic detection toward continuous quantification, organizations can close the gap between observed and actual emissions.

Quantitative Optical Gas Imaging, enabled by dual-band technology and measured in LPM, provides the foundation for accurate methane leak detection, effective mitigation, and credible ESG performance.

As regulatory expectations evolve and methane leak detection shifts toward continuous, data-driven approaches, organizations are increasingly looking for practical ways to quantify emissions in real operating environments.

To explore how continuous quantitative optical gas imaging can support methane management, ESG reporting, and operational decision-making, you can learn more about CI Sensing’s approach or schedule a demo to see how dual-band QOGI performs under real-world conditions.