The Ormat Neal Hot Springs (NHS) site is a 22 MW geothermal power plant located in Oregon, USA. Originally developed by U.S. Geothermal Inc., NHS was acquired by Ormat Technologies in 2018 along with two additional sites - San Emidio (NV) and Raft River. Since the acquisition, Ormat has been upgrading these facilities with its best-in-class technology and operational expertise.

Operational since 2012, NHS was one of the first geothermal sites to use supercritical R134A refrigerant gas as its working fluid (moto-fluid). The plant includes three production units, each consisting of a turbine-compressor-generator assembly and an ACC unit. Electricity generated at the site is sold to Idaho Power Company.

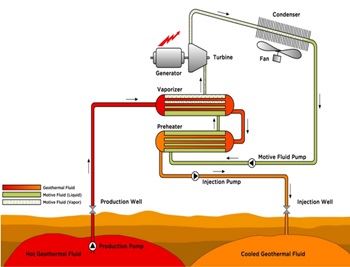

Ormat utilizes unique binary technology, which is ideal for maximizing both sustainability and long-term efficiency. Binary plants operate as closed-loop systems, reinjecting 100% of the geothermal fluid to maintain reservoir pressure and reduce environmental impact. They are cost-effective and resilient to changing reservoir conditions, ensuring high efficiency over time.

In this system, geothermal fluid is extracted from the reservoir and directed to Ormat’s Energy Converter (OEC), where it heats a secondary organic fluid with a low boiling point. The vaporized fluid drives a turbine connected to a generator. After condensation, the fluid is cycled back through the system, while the cooled geothermal fluid is reinjected into the ground—completing a clean, efficient loop.

Ormat Binary Cycle

Geothermal power production is considered one of the cleanest forms of energy. In contrast to wind and solar, it offers consistent and dependable output with minimal greenhouse gas emissions.

To ensure the efficiency of geothermal technology and facilitate quick and accurate leak detection for timely repairs and reduced environmental impact, Ormat continuously enhances its power plant operations. Typically, Ormat’s technology makes use of motive-fluids that are non-polluting. This site, however, utilizes R134A, a polluting potent greenhouse gas which has shown unstable prices in recent years.

To mitigate these two drawbacks, Ormat installed CI Sensing’s MetCam unit in NHS for continuous monitoring and early detection of gas leaks.

Each production unit at NHS is monitored by two MetCam units (6 units altogether) strategically placed 10–15 meters from key high-pressure components. These zones, where gas enters the turbine under high pressure, are more prone to leaks. Thanks to MetCam’s wide field of view, complete asset coverage is achieved with minimal units.

MetCam unit monitoring the high-pressure area

The MetCam units were specifically tuned for R134A detection and are calibrated to quantify leaks of this gas. Each unit operates autonomously, processing data onboard and minimizing site infrastructure requirements.

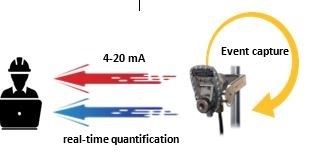

The systems are integrated with the plant’s 4-20 mA analog network, signaling normal operation and triggering an alarm (8 mA) when the amount of gas detected, during a set period, exceeds the set amount. In this site the threshold was defined as exceeding 50 liters of gas within a 60 min interval.

Additionally, the MetCam units are connected to the site’s ONVIF video interface. Using the Milestone ONVIF client, operators view real-time video feeds overlaid with gas plume data directly from the control room, enabling faster response and improved situational awareness. Conformance with the ONVIF protocol allows the site to program executive actions on alarms, such as sending SMS messages or notifying specific operators of the occurrence of a leak.

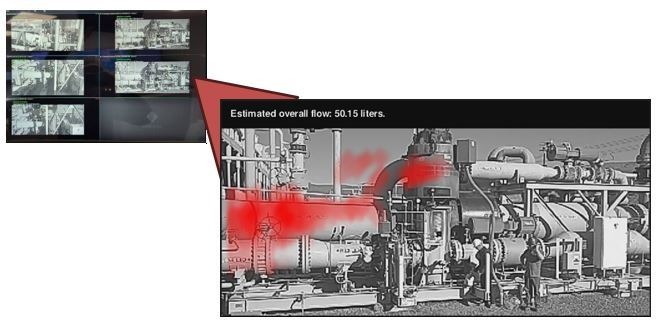

MetCam live output videos displayed on an ONVIF client application in the site control room

MetCam’s visual display enhances situational awareness by clearly showing which component is leaking, supporting faster and more informed corrective actions. When a gas leak is detected, MetCam triggers an event, overlaying the gas plume on the live video footage along with real-time quantification of the leak. Throughout the event, the system captures images and log files, which can later be used to calculate the total volume of leaked gas and analyze leak patterns for improved maintenance planning and reporting.