The Eshel HaNassi Pressure Reduction and Metering Station (PRMS) is part of Israel’s national natural gas distribution network, operated by Israel Natural Gas Lines company (INGL). As part of a six-month pilot program, CI Sensing deployed its MetCam continues optical gas imaging (OGI) system to monitor methane emissions at the site. The goal: demonstrate real-time leak detection, enhance operational safety, and ensure compliance with environmental regulations.

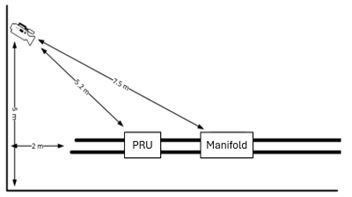

The MetCam system was installed in the station’s operation shed, positioned in the northeast corner at a height of 5 meters. From this location, it provides a clear line of sight to the pressure reduction manifold, approximately 7 meters away. To ensure full coverage of the piping, the system was mounted at a 90° tilt. Two modes were activated during the pilot: Safety Mode, for immediate detection of hazardous concentrations, and Emissions Mode, for identifying and quantifying even the smallest leaks.

Throughout the pilot, periodic site reviews were conducted at intervals of 1–2 weeks. Each review included analysis of potential leak events, review of stored data, and system calibration as needed. Findings were reported to the operations team at INGL. In some cases, additional actions were taken, such as software updates and documentation of controlled releases.

While MetCam operated reliably throughout the pilot, the lack of real-time integration with INGL’s SCADA system limited its use to post-event analysis. For full operational value, live alerts should be linked directly to the site’s control infrastructure.

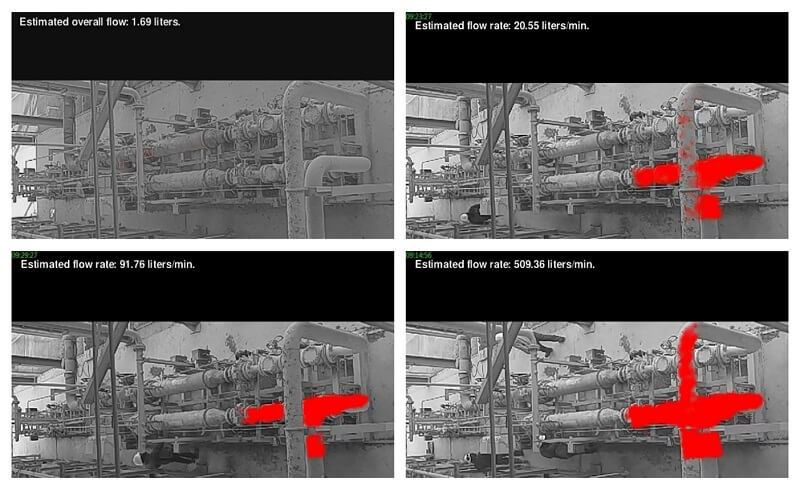

Two rounds of controlled methane releases were conducted during the pilot. During these tests, valves were opened at varying flow rates and locations along the manifold to evaluate the system’s response. MetCam successfully detected all releases, triggered alarms for explosive methane concentrations in the area, and generated emission reports summarizing the volume of gas released during each interval. As no flow meter was installed on the release valves, it was not possible to directly compare the system’s quantification to exact flow measurements.

The pilot confirmed MetCam’s value as a reliable, continuous monitoring tool. Its wide field of view, automated detection, and real-time alerting offer a powerful tool for emissions control and regulatory compliance. Following the successful demonstration, further integration with site systems and potential expansion are under consideration.